|

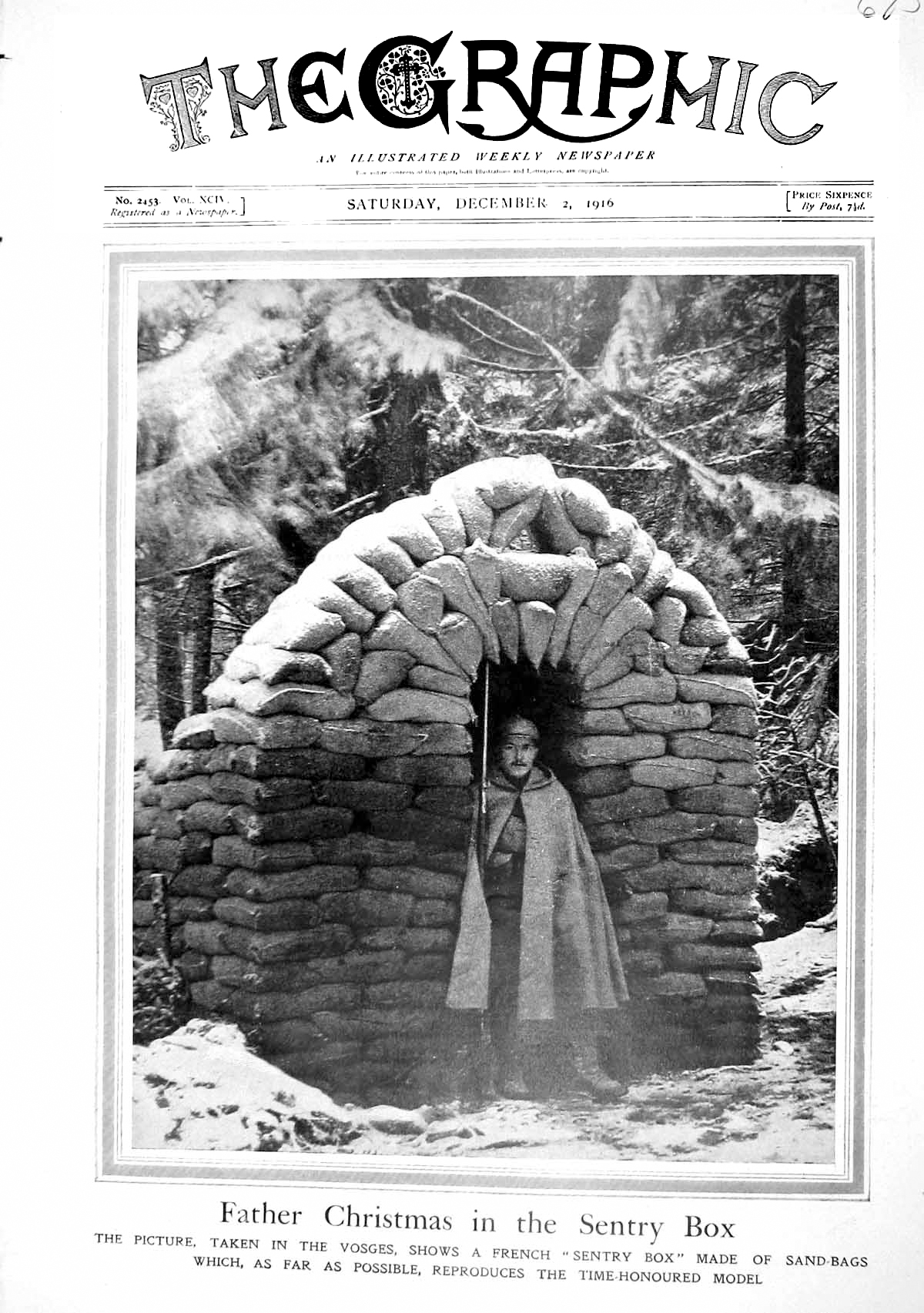

Earthbags If you're new to earthbags, we just offering a brief overlook on the fundamentals. There are plenty of books & websites out there that go deeper into the subject than we do. The best way to learn, though - as with so many other things in life - is by doing. Getting your hands dirty, so to speak. Start with the basics. Take some clay-rich dirt in your hand. Not too much; you don't want your dirt to have more than about 30% clay. Moisten it, squeeze it, roll it into a snake. Now add a little sand, squish it into a form, lay it in the sun & let it bake for a few days. It gets hard. Congratulations... you've just made adobe. If you put this wet clay/sand mix in a sandbag & stack the bags, pound them flat, smoosh them around to your liking (straight lines, curves, rounded corners, whatever) and let them dry, then you have earthbags - modular building blocks, adobe bricks in a bag. With the right fill & a little finesse, earthbags are stronger & more stable than concrete blocks. They're low-cost, low-tech, have a relatively low carbon footprint, they're fireproof, and - depending on your fill material - are free of the chemicals & outgassing (formaldehyde, etc.) that are increasingly common with many modern building materials. History: The idea of using dirtbags or earthbags isn't new; think of the sandbag trenches &  fortifications from World War I. The Industrial

Revolution allowed mass production of textiles, and bags

of dirt were used

as far back as the Revolutionary War.

Before that, baskets filled with dirt & rocks (the

predecessors to gabions) were used for fortifications as

far back as Mesopotamian times.

fortifications from World War I. The Industrial

Revolution allowed mass production of textiles, and bags

of dirt were used

as far back as the Revolutionary War.

Before that, baskets filled with dirt & rocks (the

predecessors to gabions) were used for fortifications as

far back as Mesopotamian times. But the application of bags with wet fill (mud) that sets up hard, as an alternative building material, is fairly new. It dates back to around the 1960s and can be largely credited to two individuals. One was Edward Dicker, who patented the "Stack-Sack" process in the 1960s (burlap sacks filled with a dry mix of sand, cement, and gravel; soaked in water & then stacked, with rebar driven through every couple of feet to anchor them). Further refining the concept was Iranian architect Nader Khalili, humanitarian and founder of the Cal-Earth Institute, who recognized that people left homeless in war zones and disaster areas around the world often have (if little else!) abundant access to three things; sandbags, barbed wire, and dirt. Earthbags are ideal for bordering sinuous walkways, garden beds, terracing, erosion control, building arches, serving as foundations or stem walls for cob or straw-bale constructions, or more ambitious projects. Once they're fully cured & well plastered, no one would know that they're not adobe (or something more conventional). Advantages:

DIY: With the basic materials (bags, dirt, barbed wire to lock rows of bags together, and a tamper), anyone can design and build with earthbags. If your dirt doesn't have sufficient clay (at least 20%, no more than 35%), you can add it, or stabiize it with lime or cement. Alternatively, filling your bags with dry scoria (lava rock) avoids the need for mixing soils or adding water. The voids in the scoria provide significant insulation (R-value) and the bags are lighter in weight (easier to work with). One huge advantage is that you can build year-round (unlike earthbags, which require warm daytime temperatures for the mud to cure). We can provide earthbags pre-filled with scoria by the pallet if you're interested. You don't even need to buy bags. Sure, we're happy to sell them to you. But some people have had success using alternatives like thrift-store pillowcases, sheets sewn together, etc. The point is to have a container or wrap that will hold & confine the wet fill, and that will survive the tamping without splitting a seam. Once the contents of the bag have cured & and your construction is plastered, it matters little what the bag was made of. It'll be on you, though, to ensure that everything's straight & level. Bags make it much easier. If you're new to this, you'll find information, links, and resources on these pages & elsewhere to help you get started. Empty bags (click HERE to see prices): Standard polypropylene bags are14"x26" (approx. 36 cm x 66 cm) and can hold up to about 50 lbs. of fill. These are medium-weight (10x10 weave, 850 denier, superior to the cheap bags sold online), have tie strings, and are UV treated to provide about 6 months of protection. Large polypropylene bags are the same as the above, but measure 18"x30" and can hold between 75 and 100 lbs. of fill. These can be difficult to manage when using for building. Natural burlap bags (new, additive-free, 9 oz. weave, 14"x26") are a bit expensive for construction but are excellent for gardening and matanzas. We occasionally carry larger untreated burlap bags (18"x30" and 23"x40") which, among other things, are just the thing for sack races. Treated burlap bags (dipped in a copper solution to help prevent rot, mildew & to deter critters) run about 12"W x 14"L and are $2.00 each. These meet US military specs CID A-A-52141 and are made in the US. Good for erosion control and that underground bunker that you've been thinking about. Specialty bags include:

Tools: We provide 4-point barbed wire in rolls or by the foot. This is used between the courses of bags to lock them together. We also provide tampers, bag fillers, sifters, zip ties, trowels - pretty much anything you need. See our store here. If you live out in the boonies & want us to find you something to add to your order (whether it's a mantle for your Aladdin lamp or chocolate espresso beans from Trader Joes), we'd be happy to look around & give you a quote. Plastering: After building, you'll need to cover your structure. Popular materials include lime, cob, adobe mud, papercrete, stucco, and earthen plasters. Typically, you'll want to add one or more rough basecoats, and then a finish coat that will add color, texture, durability, and weatherproofing. Check out our plastering/rendering pages (in progress!). home

|

store

| getting

started | computations

|

techniques

plastering | links | about us | contact *

New Mexico residents, please add NM gross receipts tax

of 7.9% to all orders.

All sales are final. Defective merchandise will be cheerfully replaced at our discretion. 505.750.3478 (DIRT)

no answer? Leave a message! |

Click

here

to

check out the USDA's NRCS Web Soil Survey mapping engine to see what kind of soil is on your land! Soil type testing guidelines HERE Why not to use concrete (cinder) blocks        |